Through the result of shrinkage in the sheet as it progresses to the trim station, knives that are in a fixed position are more likely to produce an inconsistent trim register. Sharples’ multiple mounting options for floating and locating your die will assist in producing consistent parts throughout your mold layout. Floating dies, whether with a retainer or counterbored die base, will work well with the multiple locating options machined locators, laser-cut rings, milled pockets or cone locators. Sharples can help locate your formed parts and produce a consistent flange. Predicting shrinkage is based on layout, material and sheet progression. Every formed part and job can be different, having experience with different layouts and tooling options are what separates Sharples from our competitors.

- CREATIVE. INTRICATE. EXCEPTIONAL.

- Email:

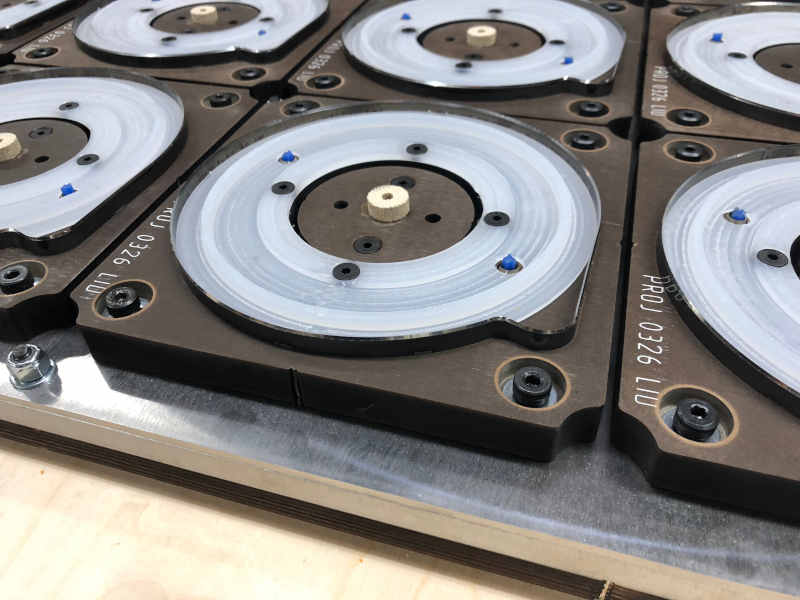

Floating Steel Rule Dies

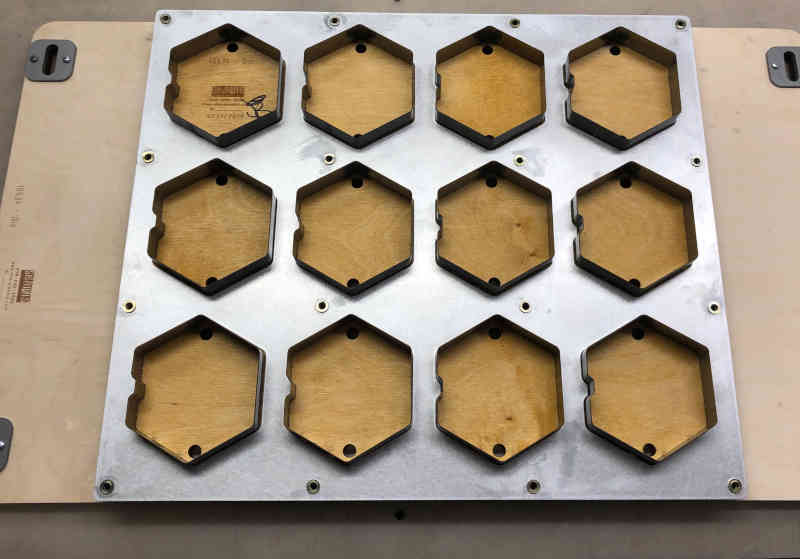

Retainer Plates

Capturing the dies in a frame providing the maximum float.

Male Locators

Locators Finding the features on the part, producing an even flange.

Milled Pockets

Assisting with clearing and locating the formed parts.