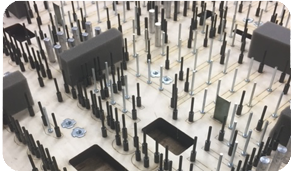

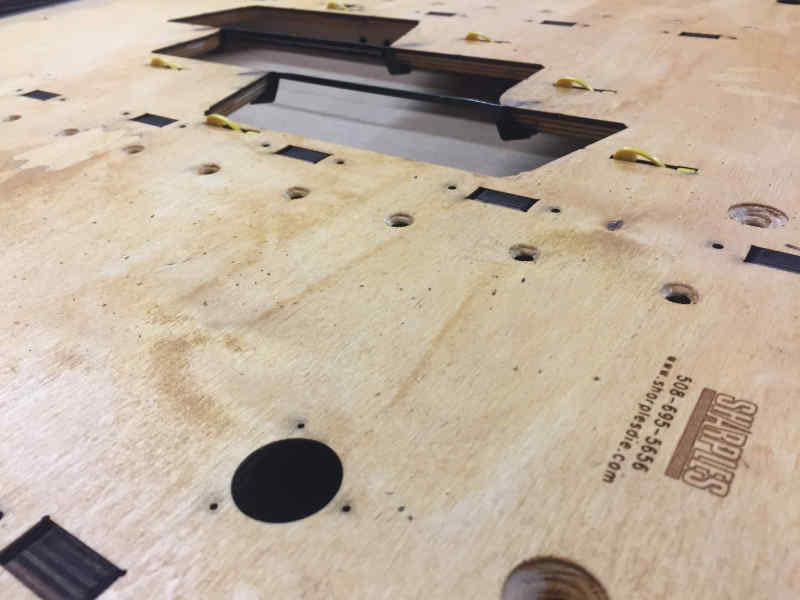

Power stripping virtually eliminates the need for bottom pins. Sharples follows industry machine specifications in design and manufacturing to produce the optimal stripping unit that will work in today's high-speed, sheet-fed machines. We have experience with various difficult stripping layouts and different stock types. Unique capabilities including steel and laser cutting enable us to provide custom stripping rules and steel inserts to help our customers strip out the most detailed scrap areas and run at high production speeds.

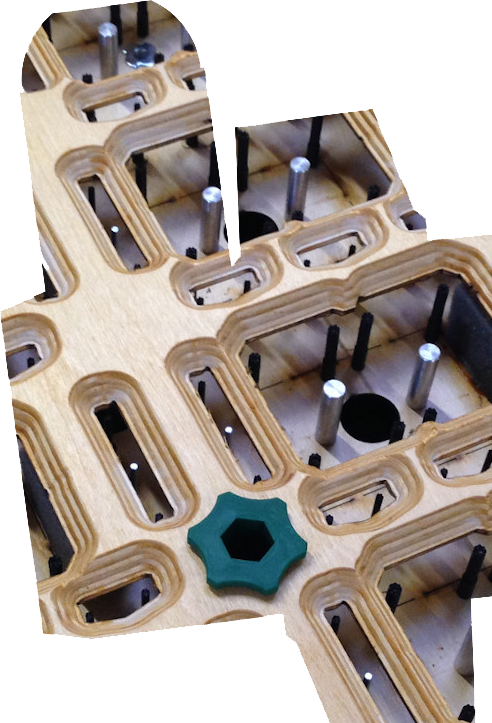

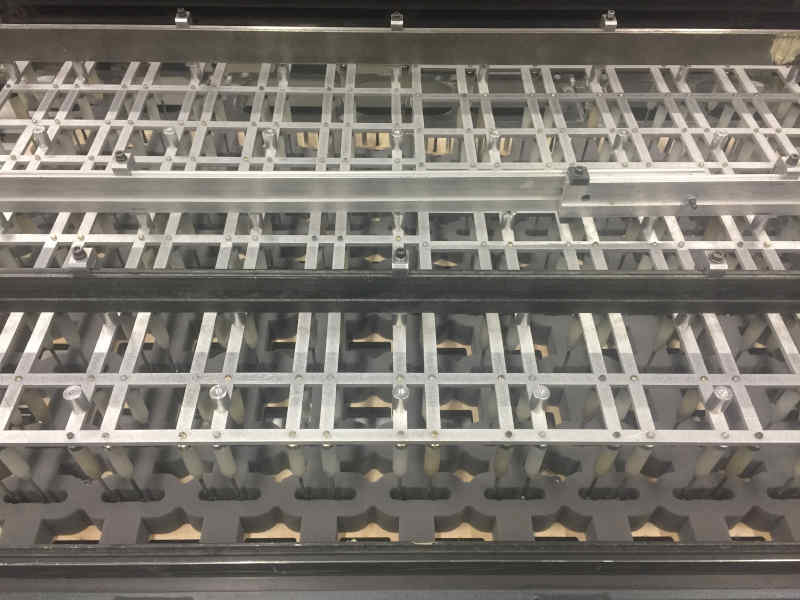

For detailed stripping jobs, a custom bottom pin tool can save a press' set up time. Sharples bottom strippers are engineered to work in conjunction with all other tooling, designed to have scrap drop out properly and pull it out of the way. Sharples’ engineering, planning, and design can assist structural design and prepress with tools that can be utilized to work on multiple layouts. Sharples can also design small sections to mount to existing frames. The strippers can remove small scrap or scrap that is too close to use standard bottom pins.

Sharples can set up unique standards that work with your company's requirements. We merge preferences to work with current machine specs, that is a Sharples customer service standard.