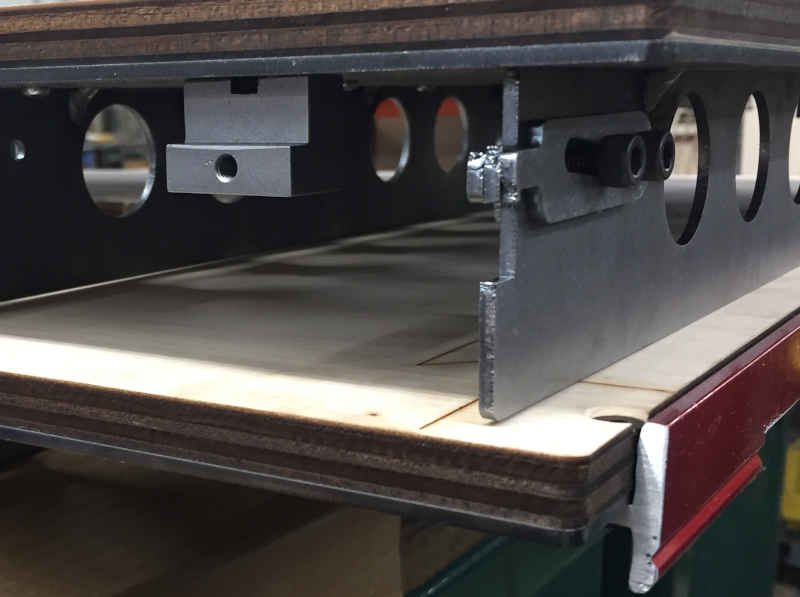

Blank separation is an essential part of the finishing process. Accurately designed tools can result in faster run times and less handling. All Sharples blankers are built to work in with other tools throughout the sheet-fed process. Sharples designs all tooling with Bobst certified software and has the experience to provide customers with blanking tools for most layouts. These include thin stock and heavy stock, single and double knife configurations, and combination runs. We encourage our customers to take advantage of blanking technology to save on labor, but we understand the cost of a complete tooling package can be high. To help customers save on tooling costs, we can set up a customized system and build components for their blanking tools.

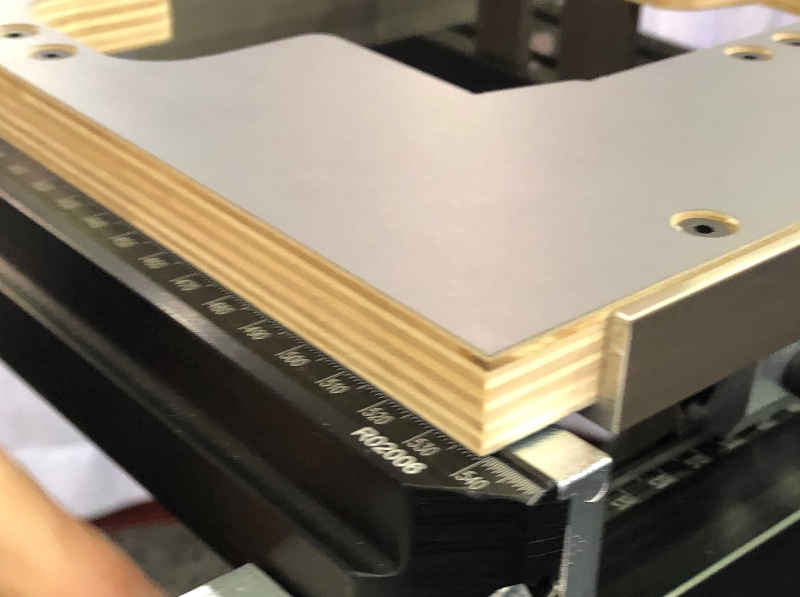

Blankers press ready with frames are designed for long-running items. Sharples can manufacture aluminum, steel, Light Blankers or BSI blankers using the best in laser, machining, welding, and bending technology. Steel blankers designed to stand the test of time. This is a solid solution made custom for you.

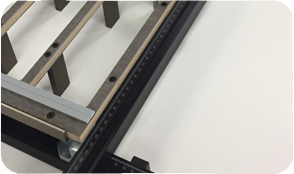

Flat top Blankers: Steel or wood or a combination of the two. Double knife or made with an insert grid. Can be made with either Sharples frame, Bobst flat top or BSI's Angle Lock frame.

Component Blankers: An economical solution that Sharples provides to customers who do not want the expense of dedicated tooling. Many options are available to suit your prepress setup. Sharples will work with you to find the best solutions that work for quick set up while saving on tooling cost.